Cleaning out the vacuum recover tank is a vital part of the daily maintenance on your No-Touch Cleaning System. Cleaning out the vac tank helps prevent foul-odors as well as a lack of suction produced when the float shut-off valve inside the tank becomes clogged.

Kaivac 2750 Maintenance Videos

Check Hoses

Inspecting cords and hoses for safety efficiency.

Wipe Down Machine

On a daily basis, it is good practice to wipe down your No-Touch Cleaning System. Wiping your machine down will keep dirt, residue, and chemistry from accumulating on your system. This keeps your machine looking and functioning good.

Squeegee Blade Inspection

How to properly inspect the blades on your squeegee heads for wear or damage.

Cold Weather Storage

How to ‘winterize’ a No-Touch Cleaning system stored in below freezing temperatures.

Release Spray Line Pressure

At the end of every cleaning process it is important to release the pressure built up in the spray line to keep your chemical injection system functioning properly.

Lubricating Components

On a weekly basis you will want to lubricate a couple components of your No-Touch Cleaning System to keep them operating at their peak performance. Use WD-40 or White Lithium Grease to lubricate the spray gun and chemical selector valve.

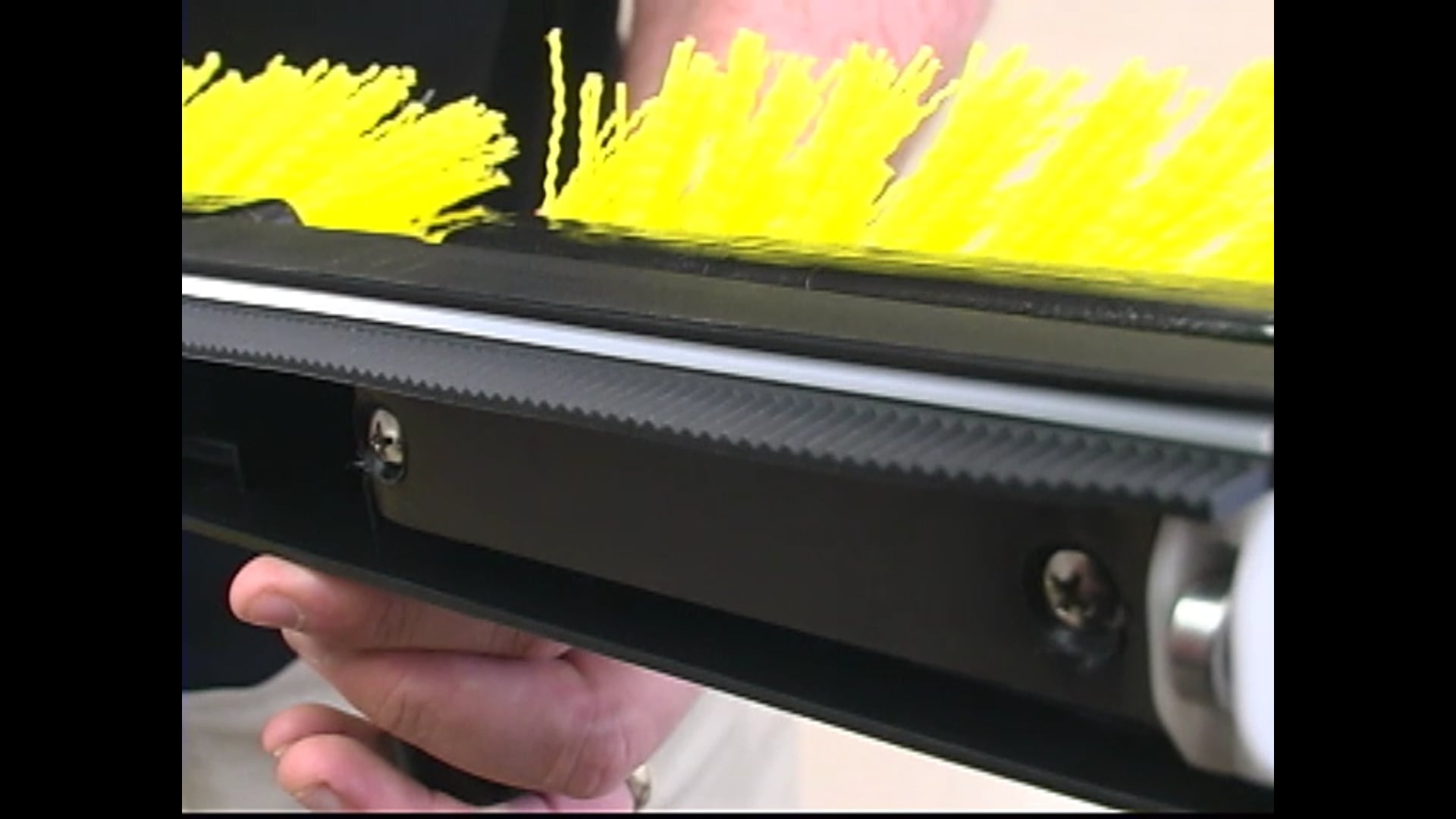

Squeegee Blade Replacement

The squeegee head is one of the most important parts of your Kaivac system to maintain. Fortunately, it’s also one of the easiest to troubleshoot and correct.

Inspect HEPA Filter

How to make sure your HEPA filter is clean and dry.

Squeegee Head Replacement

One of the largest wear and tear components on your No-Touch Cleaning System is the squeegee head. Over time the squeegee head will wear out or break, significantly affecting the performance of you No-Touch Cleaning System. Weekly inspections will help you identify...

Black Box Replacement

How to replace the Black Box on a No-Touch Cleaning system.

Inspecting Wheels and Casters

Keep your wheels and casters in top shape with periodic inspections.